Which Chemical is Best for RO Membrane Cleaning?

Looking to keep your Reverse Osmosis (RO) membranes in top shape? The best chemical for the job is citric acid for scaling and sodium hydroxide for organic fouling. In Reverse Osmosis Systems for Commercial & Industrial Applications, we explore how the right cleaning methods—and even countertop dispensers—can boost your RO system’s performance and extend its lifespan. Stick around to learn how to clean smart!

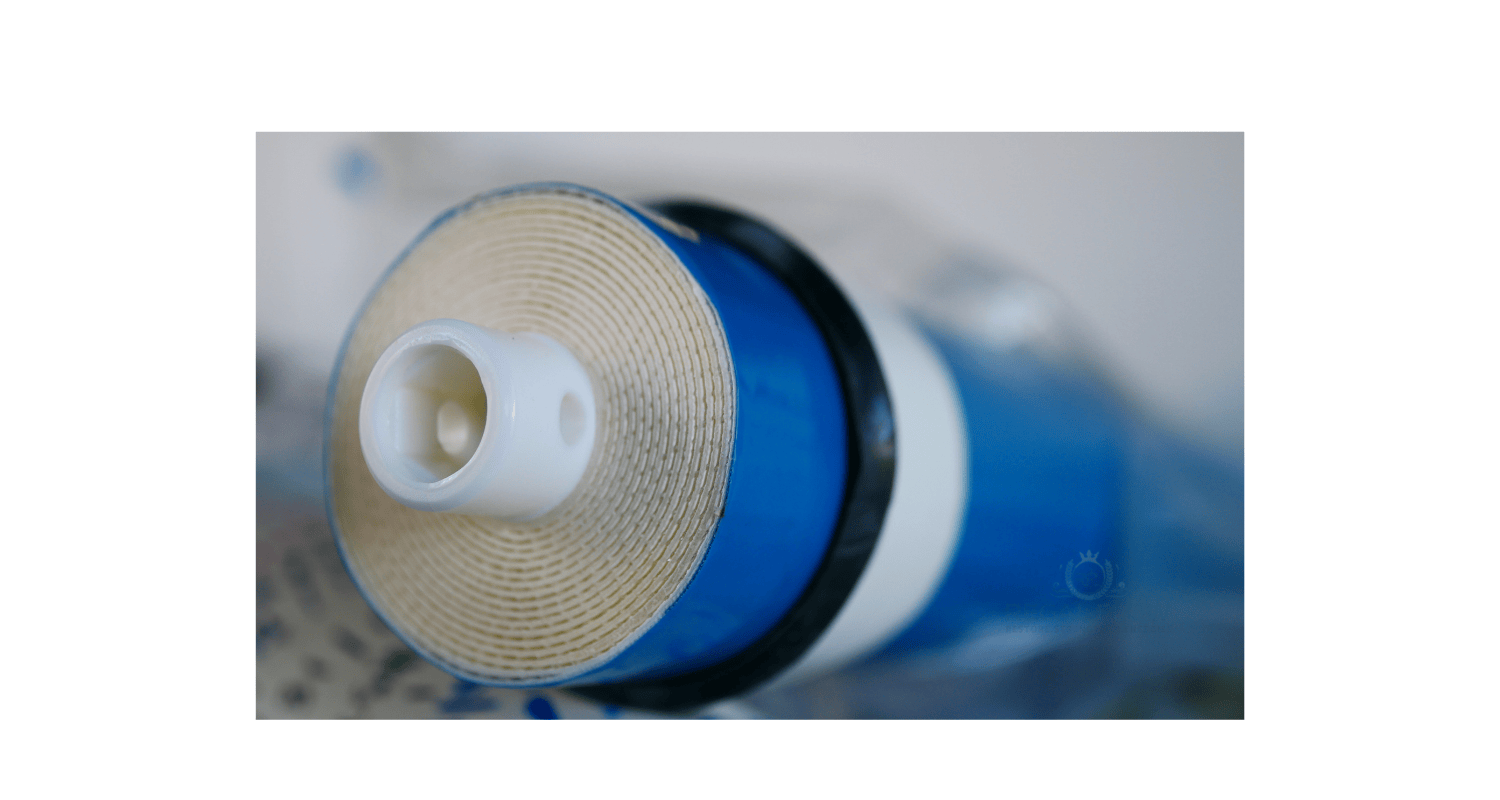

Understanding RO Membrane Fouling

Imagine your RO system as a finely tuned engine, working hard to give you clean, pure water. But, like any machine, it can suffer from a build-up of gunk. In the world of RO, that gunk is called fouling. It’s when minerals, organic compounds, or even microorganisms get stuck on the membrane, making it harder for the system to do its job.

Common Types of Foulants (Scale, Biofilm, Organic Matter)

There are three main types of fouling that plague RO membranes:

-

Scale: This is the hard, crusty stuff that forms when minerals like calcium or magnesium in the water precipitate and cling to the membrane.

-

Biofilm: It’s like a slippery slime that grows on the membrane, formed by bacteria and fungi that thrive in moist conditions. Biofilm can be tricky to remove and cause major issues.

-

Organic Matter: Oils, proteins, and other organic materials can accumulate on the membrane, reducing its efficiency. These are typically the result of contaminated water sources.

Why Regular Cleaning is Essential for RO Performance

Think of regular cleaning as a way to keep your RO system’s “engine” running smoothly. If fouling isn’t tackled, it can lead to decreased water flow, lower pressure, and reduced water quality. Cleaning keeps everything running efficiently, ensuring your system lasts longer and performs better.

Factors to Consider When Choosing a Cleaning Chemical

Choosing the right chemical for cleaning your RO membrane isn’t just a matter of picking whatever’s on sale. You need to consider a few important factors to make sure you get the right solution without damaging your equipment.

The Type of Fouling Present

The first step is figuring out what kind of fouling you’re dealing with. For scale, you need an acidic cleaner. If biofilm is your culprit, you'll need something stronger, like a disinfectant. For organic matter, an alkaline solution works best. Understanding the specific problem makes it easier to choose the right cleaning chemical.

RO Membrane Material Compatibility

Not all RO membranes are created equal. Some are made of more delicate materials, while others can handle stronger chemicals. Always check the manufacturer’s guidelines for the best recommendations on which cleaning chemicals are safe for your specific membrane material.

pH Sensitivity of the Membrane

RO membranes can be sensitive to extremes in pH. Some are fine with acidic or alkaline solutions, while others can degrade with the wrong chemical. Always verify the recommended pH range for your membrane to avoid damaging it with an inappropriate cleaning solution.

Safety and Environmental Regulations

When it comes to choosing cleaning chemicals, safety is a top priority. Some cleaners are harsh, both for people and the environment. Look for options that are eco-friendly and comply with safety regulations to keep your system and surroundings in good shape.

Common RO Membrane Cleaning Chemicals and Their Applications

Now that you know what factors to consider, let’s dive into some of the most common cleaning chemicals used for RO membranes. Each chemical is suited to specific types of fouling, so choosing the right one is key to getting your membranes back to their best.

Acid Cleaners (Citric Acid, Hydrochloric Acid) - For Scale Removal

Acidic cleaners like citric acid and hydrochloric acid are excellent for removing scale. These acids break down mineral deposits without harming the membrane. Think of it as using a soft brush to scrub away calcium build-up, leaving your membrane ready to work again.

Alkaline Cleaners (Sodium Hydroxide, EDTA) - For Organic Matter and Biofilm

When it comes to tackling organic fouling and biofilm, alkaline cleaners like sodium hydroxide or EDTA are your go-to. These chemicals are great for breaking down oils, proteins, and the slimy biofilm that can stick to your membranes. They’re like giving your membrane a deep clean, removing the stubborn stuff that’s tough to get rid of.

Oxidizing Agents (Hydrogen Peroxide) - For Biofilm and Organic Matter

Hydrogen peroxide is another powerful cleaner, especially when dealing with biofilm and organic fouling. It works by breaking down the organic compounds and killing the microorganisms that form the biofilm. It’s a bit like using a disinfectant to wipe down surfaces, but for your membrane.

Surfactants - To Enhance Cleaning Efficiency

Surfactants are used in combination with other chemicals to boost their cleaning power. These compounds help reduce surface tension, allowing the cleaning solution to penetrate the fouling more effectively. Surfactants make the cleaning process faster and more efficient, ensuring no residue is left behind.

Determining the Best Chemical for Your Specific Needs

Choosing the right chemical is about more than just reading the label. To make sure you’re using the best solution, consider a few key factors like the quality of your feed water and the type of fouling you’re dealing with.

Analysing Feed Water Quality

The quality of your feed water directly affects the type of fouling you’ll encounter. High levels of minerals can lead to scale, while high organic content can lead to biofilm. Knowing the composition of your feed water helps you choose the right cleaning chemical to address the specific fouling.

Identifying the Predominant Foulant

Once you’ve analysed your water, the next step is identifying which type of fouling is most common. If scale is the primary issue, an acidic cleaner is best. For biofilm and organic fouling, you’ll need an oxidizing agent or an alkaline cleaner.

Consulting Membrane Manufacturer Guidelines

Always refer to your membrane manufacturer’s guidelines before choosing a cleaning chemical. They provide specific recommendations tailored to your membrane’s material and construction. Following these guidelines ensures that your cleaning routine is both effective and safe.

RO Membrane Cleaning Procedures and Best Practices

It’s not just about the chemicals – how you clean your RO membrane is just as important. To get the best results, follow these tried-and-true cleaning practices.

Pre-Flushing the System

Before you start cleaning, it’s important to flush the system with water to remove any loose debris. This helps ensure that the cleaning chemical can target the fouling directly, without interference from larger particles.

Preparing the Cleaning Solution

Mix your chosen cleaning chemical according to the manufacturer’s instructions. The right concentration is crucial for effectiveness. Too strong, and you risk damaging the membrane; too weak, and the cleaning won’t do much.

Circulation and Soaking Times

Once the solution is prepared, circulate it through the system to ensure it reaches all areas of the membrane. Allow the solution to soak for the recommended amount of time to break down the fouling effectively.

Rinsing and System Start-up

After the cleaning process, rinse the system thoroughly to remove any chemical residues. Once rinsed, start up the system and check for restored performance, ensuring the membrane is functioning properly.

Conclusion: Selecting the Right Chemical for Effective RO Membrane Cleaning

Cleaning your RO membranes isn’t just about grabbing the first cleaner you see on the shelf. By understanding the type of fouling, considering the membrane material, and following proper cleaning procedures, you can ensure that your system runs smoothly for years. Choose the right chemicals, and your RO system will continue to provide pure, high-quality water every time.

More Reverse Osmosis info we think you'll love

RO Systems in the Food & Beverage Industry: Enhancing Quality and Compliance

Implementing RO Technology in Hospitality: Elevating Guest Experience

Reverse Osmosis in Healthcare and Laboratories: Ensuring Purity and Safety

Optimising Coffee Shop Operations with RO Water Filtration

Selecting the Right Commercial RO System for Your Business

Maintaining Your Commercial RO System: Best Practices and Tips

Industrial Reverse Osmosis Cost per Gallon

Commercial Water Filtration Systems

Industrial Reverse Osmosis System Cost

Light Commercial Reverse Osmosis System

Reverse Osmosis Pressure Vessel

Reverse Osmosis vs Carbon Filter

Leave a comment